Composite Materials and Structures

for the Marine Environment.

Case studies: offshore structures, naval vessels, yacht hulls, canoes, sailcloth. |

|

This page is primarily intended to support University of Plymouth students in the School of Marine Science and Engineering (Faculty of Science and Environment) studying on the BSc (honours) Marine and Composites Technology and formerly on the BSc (honours) Marine Sports Technology degrees.

Marine renewable energy systems (e.g. wind turbines, wave power and tidal stream [1] and tidal barrage)

See the MATS347 Energy webpage for some basic information and resources on

sources of energy. Scarr et al [2] define the following locations for marine renewable energy devices:

- at shore: sited at a shoreline location on land

- near shore: in open water, within 12 miles of the shoreline and normally less than 50 m water depth

- offshore: in open water, more than 12 miles from the shoreline and normally more than 50 m water depth

Pérez-Collazo et al [3] have reviewed the state of the art for combined/integrated wave and offshore wind energy. They distinguished three classifications: co-located (lower risk and development costs), hybrid (the focus of most R&D to date) and island (early stage development) systems.

The principal systems used to harvest the energy are (a) offshore wind turbine arrays, (b) wave energy devices and (c) tidal turbines, albeit that the latter two systems are still at an early stage of development. Other systems include Ocean Thermal Energy Conversion (OTEC), salinity gradient and algal biomass. Water is 830 times the density of air (or more at depth), so the forces generated are significantly increased [4] and the salt water environment increases the prospect of material degradation [5, 6]. Further, where devices will be located offshore and at depth there is a need to ensure the device will continue to operate over extended timescales withouth intervention for maintenance and repair.

The Ming Yang Smart Energy OceanX platform houses a 50 MW dual floating wind turbines [7]. It would be almost double the capacity of the current strongest wind turbine. The platform will be engineered for waters deeper than 40 meters and have V-shaped floaters (Figure 1).

Figure 1: The MingYang floating twin turbine wind energy device (image MingYang via Balkan Green Energy News).

Wood [8] reviewed wave energy renewable energy devices and identified more than 40 companies with devices at the prototype ordevelopment phases. wave energy devices can be classified as:

- attenuator technology, e.g. McCabe Wave Pump and Pelamis.

- oscillating water column (OWC) technology, e.g. airWAVE, HydroAir, Limpet, Oceanlinx (glass-reinforced composite diffuser and nacelle) and Wavegen.

- oscillating wave surge converters (OWSC), e.g. Oyster (buoyant hinged flap), WaveRoller (fibreglass wings).

- overtopping devices/floating reservoirs, e.g. WaveCat [9, 10] or Wave Dragon.

- point absorbers/submerged pressure differential devices, e.g. Archimedes Wave Swing, PowerBuoy and PS Frog.

Mohan [11] considered the advantages of composite materials in marine renewable energy devices, specifically the stator, rotor and blade for a 2 m prototype C-Power underwater tidal turbine. The 1.2 MW SeaGen tidal energy convertor developed by Marine Current Turbines in collaboration with Aviation Enterprises Limited (AEL) [1, 2]. The 16 m diameter system is installed in Strangford Narrows (Northern Ireland). Each of the blades is based around a hollow box carbon fibre composite spar with carbon composite ribs and a glass fibre composite envelope. SeaGen also uses glass reinforced plastic (GRP) for the large fairings on the cross-arms that support the twin turbines and in the top housing. The Ocean Flow Energy Evopod tidal stream system, a semi-submersible floating device held in position by a moored buoy, was also trialled in Strangord Narrows with a 1.5 m diameter rotor (one-tenth scale producing 1 kW) [2]. The one-fifth scale 22 kW prototype, designed with glass reinforced epoxy composite rotor blades with selective use of carbon composite to stiffen the largest blades, will be grid-connected.

Figure 2: The SeaGen tidal energy converter installed in Strangford Lough (from Power Technology)

The Pulse Tidal oscillating hydrofoil tidal stream system was installed as a 100kW prototype in the River Humber estuary near Immingham [2]. Each foil has a box-section carbon fibre/epoxy composite spar, to take the primary bending loads, bonded to glass fibre/epoxy envelope skins around a PVC structural foam core.

References

- P Harper, S Hallett, A Fleming and M Dawson, Advanced fibre-reinforced composites for marine renewable energy devices, Chapter 9 in J Graham-Jones and J Summerscales (editors), Marine Applications of Advanced Fibre-Reinforced Composites, Woodhead Publishing, Cambridge, 2015, 217-232.

- D Scarr, R Kollek and D Collier, Wave Energy: Technology Transfer and Generic R&D Recommendations, ETSU report V/06/00187//REP, 2001. DTI Pub/URN 01/799.

- C Pérez-Collazo, D Greaves and G Iglesias, A review of combined wave and offshore wind energy, Renewable and Sustainable Energy Reviews, February 2015, 42, 141-153

- George Marsh, Wave and tidal power - an emerging new market for composites, Renewable Energy Focus, 14 May 2009.

- TJ Searle and J Summerscales, Review of the Durability of Marine Laminates, Chapter 7 in G Pritchard (editor): "Reinforced Plastics Durability",

Woodhead Publishing, Cambridge, November 1998, pp 219-266. ISBN 1-85573-320-x.

- J Summerscales, Durability of composites in the marine environment, Chapter 1 in Peter Davies and Yapa DS Rajapakse (editors): Durability of composites in a marine environment, Springer Solid Mechanics and its Applications series vol. 208, pp 1-13. Springer, Dordrecht, 2014. ISBN 978-94-007-7416-2. E-book ISBN 978-94-007-7417-9.

- I Todorović, Mingyang presents ultralarge floating twin wind turbine concept, Balkan Geen Energy News, 28 October 2025.

- K Wood, Wave energy conversion, Composites Technology, October 2010, 16(5).

- H Fernandez, G Iglesias, R Carballo, A Castro, M Sánchez and F Taveira-Pinto, Optimization of the WaveCat wave energy converter, Coastal Engineering Proceedings, 2012, 33, 1-8.

- H Fernandez, G Iglesias, R Carballo, A Castro, JA Fraguela, F Taveira-Pinto and M Sanchez, The new wave energy converter WaveCat: concept and laboratory tests, Marine Structures, December 2012, 29(1), 58-70.

- M Mohan, The advantages of composite material in marine renewable energy devices, Marine Renewable Energy Conference, RINA, 2008.

Offshore structures

Composite materials are used for a wide variety of applications in the

offshore oil exploration and exploitation industries as a consequence of their

low weight and good corrosion resistance. An excellent overview of "Composites for Offshore Applications" is presented by MS Babu, S Baksi, G Srikanth and S Biswas on the TIFAC website,

including the following summary Table and Figures:

Table 1: Offshore applications of composites

from http://www.tifac.org.in/news/acoffshore.htm

| Offshore | Applications |

|---|

| 01 | Composite Grids/Gratings |

| 02 | Hand Rails and Ladder Components |

| 03 | Aqueous Piping System |

| 04 | Water and fuel storage tanks and vessels |

| 05 | Low pressure composite valves |

| 06 | Spoolable type thermosetting tubes |

| 07 | Sump Caissons and pull tubes |

| 08 | Cable support systems |

| 09 | Modular paneling for partition walls |

| 10 | High pressure accumulator bottles |

| 11 | Flexible and Floating Risers, Drill pipe |

| 12 | Sub–sea structural components |

| 13 | Boxes, housings and shelters |

| 14 | Fire water and sea water lift pump-casings |

| 15 | Tendons |

| 16 | Offshore bride connecting between platforms |

| 17 | Fire and Blast protection |

|

|

|

|

|

| grids and gratings |

handrails |

ladders |

caissons |

piping |

Figure 3: Offshore applications of composites (from http://www.tifac.org.in/news/acoffshore.htm)

Composite pipe technology enables the offshore industry to operate in deeper and harsher environments. The first composite drilling riser joint was tested on the Heidrun platform in the Norwegian Sea in 2001. A fully composite 76 mm pre-commissioning downline was used offshore Brazil in a water depth >2100 m in 2014.&nbs; Despite the high material cost and limited track record for composites offshore, they are lightweight with high strength and resistance to fatigue and corrosion (hence relatively low maintenance costs), and have a low axial and bending stiffness in comparison to steel so can be formed into complex shapes (good for reel lay). 2H Offshore performed a comparison of a deepwater production Single Line Hybrid Riser (SLHR) using both steel and composite pipes at 2000 m water depth. The change to composite allowed reduced bulk of the buoyancy tank and the riser assembly frames as a result of the enhanced weight-to-strength ratio of the pipe section. Further, installation required reduced lift capacity and was quicker [1].

Reference

- P Hopkins, H Saleh and G Jewell, Composite riser study confirms weight, fatigue benefits compared with steel, Offshore magazine, October 2015, 75(9), accessed 03 November 2015.

More information:

-

MS Babu, S Baksi, G Srikanth and S Biswas:

Composites for Offshore

Applications

-

Composite materials in

offshore oil and gas industry (Philip Medlicott Ltd)

-

The Use of Fire-safe Phenolic Composite Materials in Marine Applications

(Borden Chemical)

-

Properties for offshore (reinforced) rubber oil hoses

-

GRP/PU spar buoys (e.g. SG2 and SG7 from Balmoral Group)

-

Oil and Gas

Project List (Solent Composite Systems)

- M Roseman, R Martin and G Morgan, Composites in offshore oil and gas applications, Chapter 10 in J Graham-Jones and J Summerscales (editors), Marine Applications of Advanced Fibre-Reinforced Composites, Woodhead Publishing, Cambridge, 2015, 233-257.

- R Sen, Underwater repair with composites, Chapter 11

in J Graham-Jones and J Summerscales (editors), Marine Applications of Advanced Fibre-Reinforced Composites, Woodhead Publishing, Cambridge, 2015, 259-278.

- P Hopkins, H Saleh and G Jewell,Composite riser study confirms weight, fatigue benefits compared with steel, Offshore, 10 September 2015, 75(9).

Dock infrastructure

Jacksonville (Florida) Port Authority installed pultruded composite fixed and floating dock structures capable of withstanding Category 3 hurricanes (winds to 241 kph and sea storm surge to 3.66 m) meeting "all of the technical and grant-funding requirements, including budget and timeline" when all previous bids were 50% over-budget.

More information:

Submarines and submersibles

US Navy Los Angeles-class submarines

SSN 691 "Memphis" [USNI website] was redesignated an

experimental submarine during 1989 to test composite hull structures, unmanned

underwater vehicles, advanced sonars, hull friction reduction, and so forth but

remains combat-capable. During a mid-1990s refit, SSN 691 received a GRP

turtleback abaft the sail to accommodate remotely operated vehicles and a

towing winch and drum for experimental towed sonar arrays, 4.27-m-high by

1.37-m-wide vertical surfaces at the ends of the stern stabilizers to

accommodate sonar transducer arrays, a 54-mm-diameter towed array dispenser in

the port fin (leading to the new winch abaft the sail), supports for the stern

stabilizers, new hydraulic systems, a fiber-optic databus, and 58 standardized

equipment racks to accommodate a wide variety of electronic test gear; the

modifications added about 50 tons to the displacement, most of it aft. SSN 691

has tested a composite material propeller shaft of about half normal

weight.

The American nuclear submarine SSN 711 "San Francisco" hit an

uncharted seamount on 7 January 2005, killing one sailor and injuring sixty

others, 23 of them so seriously they could not perform their duties. Facts about

the incident were slow to emerge. Dunningan states "It appears that the sub was

traveling on a course it was ordered to follow, at a depth of 500 feet and a

speed of about 56 kilometers an hour. This was the first time the navy had given

the speed of a Los Angeles class sub as anything but “25+ knots” (45 kilometers

an hour)".

Figure 4: The American nuclear submarine SSN 711 "San Francisco"

Image sources: left,

centre and

right

More information:

Perry Slingsby LR5 rescue submersible

The LR5 rescue submersible has an advanced composite pressure hull.

It normally carries three

crew members, the pilot, a co-pilot and the systems operator and up to 15 submarine survivors can be evacuated at a time.

LR5 was used in the Kursk

submarine rescue attempt.

Figure 5: Perry Slingsby LR5 rescue submersible. Image sources:

left and right and centre.

More information:

Rehabilitation of Royal Navy submarines

Babcock Composite Technology Group (at the Plymouth Devonport Royal Dockyard) have developed a composite repair technology to replace the corroded 1000 mm long by 200 mm OD sea tubes on HMS Vigilant (a Vanguard class Trident submarine) during the three year Long Overhaul Period and Refuel (LOP(R)). The time required to refurbish the 11 tubes has been cut by around 75% (down from eight months to two months). The composite repair method offers health and safety benefits, with minimised manual handling in difficult spaces, and a significantly reduced welding requirement (traditionally around 100 hours per tube).

Oceangate Cyclops/Titan

OceanGate Incorporated has announced (21 August 2013) the completion of the initial design and feasibility study for its five-person Cyclops next-generation manned submersible for depths to 3000 metres (9800 feet). The vessel will feature a 178 mm thick carbon fiber hull manufactured by automated fiber placement (AFP) complemented by a large 180° borosilicate glass dome. The vessel was to be commercially available in 2016 as the only privately owned deepwater (>2000m) manned submersible available for contracts. A follow-on version capable of depths to 6000 m was planned for completion in 2016Q4 [1].

Figure 6: Oceangate Cyclops. Images from CompositesWorld Industry News [1].

CompositesWorld reported that "Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life - at 6,500-psi service pressure" [2]. The Oceangate Cyclops 2 five-person research-class submersible, was designed for a maximum depth of 4,000m. In March 2018, the project was rebadged as Titan. The vessel was constructed as a carbon fibre cylinder with titanium dome ends including a transparent viewing port. The initial design work (with a safety factor of 2.25) indicated a hull thickness of 114 mm which was rounded up to 127 mm (five inches!). The hull was reported to be made by alternate placement of unidirectional prepreg carbon fibre epoxy in the axial direction alternated with wet-wound carbon fibre epoxy in the hoop direction to a total of 480 layers. One source suggests the prepreg was beyond the recommended "shelf-life for use in airplanes" [3]. The cylinder was [vacuum-] bagged and cured in an oven for 7 days at 137°C, with no further post-cure. The stacking sequence described above suggests there are no fibres at ±45° to provide torsional stiffness, and no woven fabric layers to act as crack arrestors, in the composite cylinder.

Sadly, in mid-June 2023 the OceanGate Titan submersible was lost with all five people aboard dead after a "catastrophic implosion" during a tourist voyage [4, 5]. BBC News has images of the recovered debris being unloaded [6-8] ans subsequently released a recording of the moment at which the vessel imploded [9].

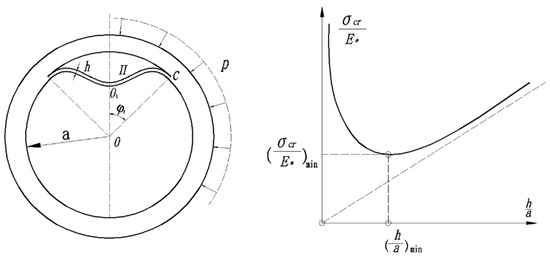

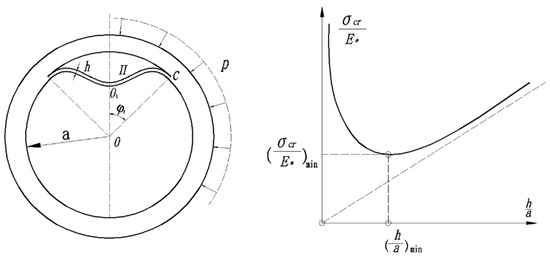

The diameter of the Titan hull was around 2 m. The pressure under water increases by 1 atmosphere for every 10 m descent, so there would be a pressure difference of ~200 hPa (20 kPa) between the top and bottom surface of the vessel. CompositesWorld analysed the lessons behind the failure [10]. Real Engineering has an interesting 15-minute video attributing the failure to snap buckling (separation of the inner layers under external pressure) [11]. Snap buckling is decribed in more detail in Li et al [12]. Five key questions that remain [13].

The United States Coast Guard report [14] concluded that the primary causal factor for the fatal incident was "OceanGate’s failure to follow established engineering protocols for safety, testing, and maintenance of their submersible, ... The investigation further identified the need for proper corporate governance, a professional workplace culture, and improved regulatory oversight, in particular for novel vessel designs and operations". The cylindrical pressure hull was ~2.5 m long with an internal diameter of ~1.37 m. The 128 mm thick hull was constructed with five layers of ~25mm filament wound carbon fibre composite bonded with film adhesive. A Boeing optimised design specified a CFRP hull thickness of ~178 mm in the absence of cure shrinkage and thermal residual stress, wrinkles, perforations or impact damage in the laminate. A worst-case open-hole structure was indicated to need ~813 mm of wall thickness! The Boeing preliminary report indicated that allowable strain tables did not support layups without plies oriented at 45˚, but the final Titan design had only circumferential and axial CFRP plies. The USCG report implicated the resin-rich volumes at the film adhesive and associated elongated voids therein between layers 1/2 and 3/4 as a potential stress concentration that could have been the critical feature of the structure.

The US National Transportation Safety Board (NTSB) subsequently published a Marine Incident Report [15].

Figure 7: Snap buckling delamination failure mode and critical load of deep sea thick shell

(from SQ Zhao, Research on compression test of the unidirectional composite material and the failure mechanism analysis,

Harbin Institute of Technology ~ China, 2013. (In Chinese),

via Yongsheng Li et al in Journal of Marine Science and Engineering, 2022, 10(10), 1456).- New manned submersible to feature carbon fiber composite hull, CompositesWorld Industry News, 26 August 2013.

- J Sloan, Composite submersibles: Under pressure in deep, deep waters, CompositesWorld, 10 May 2017.

- A Weissmann, Mission Titanic, Part 2: Delays and an unsettling statement from the OceanGate CEO, Travel Weekly, 21 June 2023.

- Safety investigations launched into Titan sub deaths, BBC News, 20 June 2023.

- Titanic sub: safety concerns raised about missing submersible, BBC News, 22 June 2023.

- Video shows wreckage of Titan submersible brought ashore, BBC News, 28 June 2023.

- Titanic tourist sub photos show wreckage being brought ashore, 28 June 2023.

- Titan sub: What's known about recovered parts... in 77 seconds, BBC News, 29 June 2023.

- Ship footage shared with BBC captures sound of Titan sub imploding, BBC News, 22 Ma7 2025.

- J Sloan, The lessons behind OceanGate, CompositesWorld, 31 July 2023.

- Real Engineering, The Questionable Engineering of Oceangate, June/July 2023.

- Y Li, C Yu, W Wang, H Li and X Jiang, A review on structural failure of composite pressure hulls in deep sea, Journal of Marine Science and Engineering, 2022, 10(10), 1456.

- R Morelle and A Francis, Titan sub disaster: Five key questions that remain, BBC News online, 15 September 2024.

- TF Whalen and JD Neubauer, Report of the Marine Board of Investigation into the implosion of the submersible TITAN (CG1788361) in the North Atlantic Ocean near the wreck site of the RMS Titanic resulting in the loss of five lives on June 18, 2023, United States Coast Guard MISLE Activity Number 7724663, 04 August 2025.

- JL Homendy, T Chapman, M Graham and JT Inman, Hull Failure and Implosion of Submersible Titan North Atlantic Ocean 370 nautical miles southeast of St. John’s, Newfoundland and Labrador, Canada June 18, 2023, National Transportation Safety Board, Marine Incident Report MIR-25-36, 02 October 2025.

BBC Two TV broadcast Implosion: The Titanic Sub Disaster (one hour) on 03 June 2025 and it will remain on line for one year. A fascinating insight!

... and criminal activity

Drug traffickers have built custom-made ocean-going self-propelled semi-submersible (SPSS) vessels known as "narco submarines" to smuggle cocaine from South America (usually Colombia or Ecuador) to Mexico for onward transport to other countries especially the USA. The authorities in Ecuador are reported to have seized a fully functional diesel electric submarine with a cylindrical 31 m long fibreglass hull on 3 July 2010 before its maiden voyage. The vessel, intended to be crewed by 5-6 people had an estimated capacity of ~10 metric tons of cargo, and could submerge to 20 m for long-range underwater operation.

Further information

G Gardiner, Composite solutions: cutting cost of nuclear-powered subs, CompositesWorld case study post, 2012.

Lifeboats

Balmoral Glassfibre Limited - Aberdeen

Self-righting, totally-enclosed, motor-propelled survival

craft for the offshore oil industry are manufactured in glass reinforced plastic

using fire-retardant resins. The craft range in size (6.2-8.75 m ) and can

carry 21-66 people respectively. As part of the certification trials, the

survival craft was required to withstand 30 m high kerosene flames and

temperatures of 1150°C. Throughout the fire test, the temperature inside

the craft never exceeded 27°C.

Figure 8: The Balmoral survival carft. Image from the front cover of International Reinforced Plastics Industry,

May/June 1983, 2(5), 1.

Royal National Lifeboat Institution

Figure 9: The RNLI Vessels. Images from http://www.rnli.org.uk/what_we_do/lifeboats/current_lifeboats (sequenced as in Table 2).

Table 2: The RNLI vessels. Table compiled from

http://www.rnli.org.uk/fleet.asp (no longer available)

and

http://rnli.org/aboutus/lifeboatsandstations/lifeboats/Pages/The-fleet.aspx

| |

Introduced |

Displacement |

Length x Beam |

Speed |

Construction |

|---|

| Inshore IB1 |

2003 |

338 kg |

4.95 x 2 m |

25 knots |

FRC structure with Hypalon coated polyester boat fabric |

| Atlantic 21 |

1972 |

1.4 tonnes |

6.9 x 2.44 m |

32 knots |

GRP hull with hypalon-coated nylon tube |

| Atlantic 75 |

1992 |

1.5 tonnes |

7.3 x 2.64 m |

32 knots |

GRP hull with hypalon-coated nylon tube |

| Mersey |

1988 |

14 tonnes |

11.77 x 4 m |

16 knots |

aluminium or fibre reinforced plastic |

| Shannon |

2014 |

18 tonnes |

13.6 x 4.5 m |

25 knots |

fibre-reinforced plastic |

| Trent |

1994 |

27.5 tonnes |

14.26 x 4.9 m |

25 knots |

fibre reinforced composite |

| Tamar |

2005 |

30 tonnes |

16 x 5 m |

25 knots |

fibre reinforced plastic (FRP) |

| Arun |

1971 |

31.5 tonnes |

16-17 x 5.43 m |

18 knots |

glass reinforced plastic |

| Severn |

1996 |

41 tonnes |

17x5.9 m |

25 knots |

fibre reinforced composite |

After 24 years service against a planned operational lifespan of 25 years, the RNLI established that the Severn lifeboat composite hulls can continue operational service for another 25 years. The life extension programme includes new shock-mitigating seats for the crew, new survivor space seating for casualties, and a new daughter craft that can be launched quickly for rescuing casualties in shallow waters or close to rocks [1].

More information:

- The magnificent Severn set to save lives for another 25 years, RNLI LIfeboats website, accessed 24 May 2021.

- Neil Chaplin and John Nurser, Launching the Tamar, Ingenia, December 2007, (33), 37-43.

RNLI hovercraft (introduced 2002 ) - displacement 2500kg (fully loaded

weight) - length: 7.75m - speed: 30 knots

Construction: aluminium hull with FRC topsides and fan ducts

Figure 10: The RNLI hovercraft. Image from http://www.rnli.org.uk/fleet.asp

Naval vessels

No minesweepers were built for the Royal Navy between the end of World War II and the 1960s, when the Ministry of Defence contracted Bristol Aeroplane Plastics to design, develop and build a full size glass fibre reinforced polyester centre section representative of a typical minesweeper. A case study of this

pre-production test structure can be found in Chapter 14 of Hollaway.

More information:

- AE Davey, GFRP minesweeper: pre-production test structure with box core

sandwich construction, Chapter 14 in L Hollaway, Handbook of Polymer

Composites for Engineers, Woodhead Publishing, Cambridge, 1994, pages 309-324.

ISBN

1-85573-129-0.

Royal Navy mine counter measures vessel - HMS Wilton: 450 tons - 46.3 m long - monolithic GRP

Figure 11: HMS Wilton. Image from http://www.tca2000.co.uk/wilton3small.jpg

HMS Wilton was a world leader at the time of her construction in 1973. At 450 tons, she was then the world's largest reinforced plastic ship. Unofficially known as HMS Tupperware, HMS Indestructible, or just 'the plastic duck', HMS Wilton was built to the tried and tested Coniston-class minehunter design (more usually called

the Ton class minesweeper).

More information:

Hunt class Mine Counter Measures Vessels: 725 tons - 60 m long - monolithic GRP

Figure 12:: Hunt class Mine Counter Measures Vessel.

Image from

http://www.btinternet.com/~warship/Today/hunt.htm

Table 3: The Hunt class Mine Counter Measures Vessels.

| Ship |

Pennant |

Builder |

Launched |

Completed |

Notes |

|---|

| Brecon |

M29 |

Vosper Thornycroft |

21 June 1978 |

21 March 1980 |

Decommissioned, now training ship at HMS Raleigh |

| Ledbury |

M30 |

Vosper Thornycroft |

05 December 1979 |

11 June 1981 |

Suffered major fire in 1983. Still in active service. |

| Cattistock |

M31 |

Vosper Thornycroft |

22 January 1981 |

16 July 1982 |

Crippled by an onboard fire in her engine room in 1998. Still in active service. |

| Cottesmore |

M32 |

Yarrow (Scotstoun) |

09 February 1982 |

24 June 1983 |

Transferred to Lietuvos Karinės jūrų pajėgos (Lithuanian Navy) as M53 Skalvis in 2008. |

| Brocklesby |

M33 |

Vosper Thornycroft |

12 January 1982 |

03 February 1983 |

Still in active service. |

| Middleton |

M34 |

Yarrow (Scotstoun) |

10 May 1982 |

14 August 1984 |

Still in active service. |

| Dulverton |

M35 |

Vosper Thornycroft |

02 November 1982 |

03 November 1983 |

Transferred to Lietuvos Karinės jūrų pajėgos (Lithuanian Navy) as M54 Kuršis in 2008. |

| Bicester |

M36 |

Vosper Thornycroft |

04 June 1985 |

20 March 1986 |

Decommissioned 01 July 2000. Now Greek Navy NTHI Europa. |

| Chiddingfold |

M37 |

Vosper Thornycroft |

04 May 1982 |

10 August 1984 |

Still in active service. |

| Atherstone |

M38 |

Vosper Thornycroft |

01 March 1986 |

30 January 1987 |

Decommissioned December 2017. Advertised for sale in June 2020. |

| Hurworth |

M39 |

Vosper Thornycroft |

25 September 1984 |

02 July 1985 |

Major fire caused funnel to collapse in May 1996. To refit in Portsmouth in May 2020. |

| Berkeley |

M40 |

Vosper Thornycroft |

03 December 1986 |

14 January 1988 |

Decommissioned 28 February 2001. Transferred to Greek Navy as NTHI Kallisto. Stern torn off in collision with Maersk Launceston Portuguese-flagged container ship. |

| Quorn |

M41 |

Vosper Thornycroft |

23 January 1988 |

12 April 1989 |

Decommissioned December 2017. Sold to Lietuvos Karinės jūrų pajėgos (Lithuanian Navy). Under a £55M contract for refurbishment by Harland & Wolff Appledore Shipyard [MoD press release]. |

Table compiled from data at

http://www.btinternet.com/~warship/Today/hunt.htm (no longer available)

More information:

Sandown/Racecourse class Single Role Mine Hunter (SRMH): 450 tons - 50m long - monolithic GRP

Figure 13: HMS Sandown (left) image from

http://www.btinternet.com/~warship/Today/sandown.jpg.

HMS Penzance (centre and right) images from

http://www.royal-navy.mod.uk/data/gallery/thumb/988989782t.jpg and

http://www.navy.ee/mcopest/data/ENG/picsfils/penzanze.jpg.

Table 4: The Sandown/Racecourse class Single Role Mine Hunters.

| Ship |

Pennant |

Launched |

Commissioned |

Notes |

|---|

| Sandown |

M101 |

16 April 1988 |

09 June 1989 |

|

| Inverness |

M102 |

27 February 1990 |

24 January 1991 |

|

| Cromer |

M103 |

06 October 1990 |

07 April 1992 |

renamed Hindostan as training vessel for BRNC Dartmouth |

| Walney |

M104 |

25 November 1991 |

20 February 1993 |

|

| Bridport |

M105 |

20 July 1992 |

06 November 1993 |

|

| Batch II Vessels |

| Penzance |

M106 |

11 March 1997 |

14 May 1998 |

|

| Pembroke |

M107 |

15 December 1997 |

06 October 1998 |

|

| Grimsby |

M108 |

10 August 1998 |

25 September 1999 |

|

| Bangor |

M109 |

19 April 1999 |

15 December 1999 |

the last warship accepted into service in 20th Century*. |

| Ramsey |

M110 |

25 November 1999 |

26 July 2000 |

|

| Blyth |

M111 |

May 2000 |

February 2001 |

|

| Shoreham |

M112 |

09 April 2001 |

28 November 2001 |

|

Table compiled from data at http://www.btinternet.com/~warship/Today/sandown.htm*

and

http://www.royal-navy.mod.uk/static/pages/462.html

(all ships built by Vosper Thornycroft at Woolston)

More information:

The Royal Navy is now transitioning mine countermeasures capability from ships to unmanned, autonomous units and a distributed, disaggregated force that makes use of networking, autonomy and artificial intelligence [RINA].

HMS Chiddingfold (MCMV M37) reversed into HMS Bangor (SRMH M109) in Bahrain on 19 January 2024.

[G Allison, British minehunters collide in Gulf, damage to be assessed, UK Defence Journal, 19 January 2024].

Swedish Navy Landsort class MCMV: 360 tons - 47.5m long - GRP sandwich

The Landsort class vessels are for "minehunting, minesweeping and anti-submarine warfare (ASW), but at the same time, [are] excellent offshore patrol vessels. Unlike single-role minehunters, the Landsort was conceived as a genuine multi-purpose vessel, able to perform various mine-warfare tasks. Each vessel is capable of operating as an independent unit or as a tactical command vessel".

Figure 14: The Swedish Navy Landsort class MCMV. Image from http://www.kockums.se/surfacevessels/landsort.html

The vessels displace 360 tonnes with an overall length of 47.5 m and a beam of 9.6 m. Material of construction is GRP sandwich and top speed is quoted as 15 knots.

More information:

Swedish Navy Visby stealth corvette: 640 tonnes (fully equipped) - 73 m long - "sandwich

construction carbon fibre reinforced plastic" - quoted speed of >35 knots.

"The Visby Class corvette is the first vessel in the world to have fully developed stealth technology, combined with high operational versatility. The outstanding stealth properties fundamentally change the ship's survivability and improve its mission effectiveness. Visby is a flexible surface combatant, designed for a wide range of roles: anti-surface warfare (ASuW), anti-submarine warfare (ASW), mine countermeasures (MCM), patrol and much more" [1].

Figure 15: The Swedish Navy Visby stealth corvette. Images from above and below.

She displaces 600 tons (fully equipped), is 73 m overall length with a 10.4 m

beam. Material of construction for the hull is "sandwich construction

carbon fibre reinforced plastic" giving a quoted speed of >35 knots.

Visby class ships HMS Helsingborg K32 and HMS Härnösand K33

have visited Plymouth.

More information:

- Visby class corvette - the true stealth vessel (kockums.se) pictures to download animations to download

- Visby class corvettes, Sweden (naval-technology.com)

- Fredrik Lindblom, Use of composites in the Visby stealth corvette, ACMC/SAMPE Conference on Marine Composites, Plymouth, 11-12 September 2003.

PSU Garden Reach Shipbuilders & Engineers Ltd (GRSE) in Kolkata is building two Anti-Submarine Warfare Corvettes (INS Kiltan and INS Kavaratti) for delivery to the Indian Navy in 2017. The carbon fibre composite superstructures, imported from the Kockums shipyard in Sweden were assembled and integrated with the steel main hull in Kolkota.

More information:

- Navy experimenting with composite superstructure for warships, Outlook India, 26 April 2015.

- Indian Navy using carbon fiber to build warships: the new carbon fiber composite superstructure is imported from Sweden, CompositesWorld, 05 May 2015.

Indonesian stealth boats

North Sea Boats in Indonesia produce a 63m Fast Missile Patrol Vessel (FMPV) with a wave piercing trimaran design and helicopter platform.

The vessel is constructed as a carbon fibre composite sandwich with vinylester modified epoxy resin matrix using a resin infusion process. The stealth characteristics reduce radar, infra-red, acoustic and magnetic signatures with no reverse-angle bow overhangs.

The weapons, including guns and missiles, and the 11 m high-speed rigid hull inflatable boat, are shaped to meld into the superstructure profile or discreetly concealed.

The vessel can be operated by a 23-person crew and augmented with a 7-person Special Operations Unit.

First vessel in class was the Indonesian Navy KRI Klewang-625 officially launched on Friday 31 August 2012 at the PT Lundin shipyard facility in Banyuwangi (East Java).

Unfortunately the US$12M vessel was destroyed by fire at the Banyuwangi naval port on Friday 28 September 2012 (just four weeks after the official launch ceremony).

Figure 16: Indonesian stealth boats. Image sources:

1,

2-4,

5-6.

Launch day and loss day videos are here.

Russian Navy

The Russian Navy will start trials of the Admiral Gorshkov class stealth frigate in November 2012. The vessel has carbon fibre superstructures.

More information: Alexei Mikhailov,

Russian Navy receives carbon fiber stealth ship, Izvestia, 09 October 2012.

US Navy M80 Stiletto

The M Ship Company (San Diego CA) has developed a unique "double-M"-shaped multi-hull lightweight

littoral (near shore) patrol boat for the United States Navy: M80 Stiletto (24.4m/80 ft long by 12.1m/39.7 ft-wide).

The patented planing-tunnel M-hull has unusual contours to capture air and convert wave energy into lift

to enable cruise at greater speed (>50 knots, 57.5 mph, 92 km/h) with

improved comfort and a smaller wake. It is the largest US naval vessel with principal

structures built using entirely vacuum-bagged carbon (sandwich) composites for the

hull major

structures with resin film infusion (RFI) for bulkheads and longitudinal

girders. The M80 Stiletto has a crew of three and is capable of transporting 12 Sea, Air and Land (SEAL) commandos. It also carries an 11m/36 ft rigid-hull inflatable boat and has capacity for smaller-sized unmanned aerial vehicles (UAVs).

Figure 17: M80 Stiletto touches water for the first time - the unusual hull planform features “planing tunnels” - the vessel in action at sea

Image sources: left and right

More information:

- New ship hull forms under development, High-Performance Composites, January 2005, 13(1), 14-15.

- Carbon naval vessel to be validated, High-Performance Composites, January 2006, 14(1), 16.

- DK Dawson,

All-carbon composite stealth technology joins the U.S. Navy: unique double-M hull design creates smooth air cushion for low-wake, low-weight, low-draft ship, High-Performance Composites, September 2007, 15(5), 42-47.

- C Caswell, "Holy bat-boat", Professional

Boatbuilder, October/November 2010, (127), 45-46.

The US Navy DD 21 project was superseded by the DD(X) program to become the 32-ship 186 m Zumwalt class designed to replace both frigates and destroyers with new multimission destroyers. The upper-section deckhouse, a composite helicopter hanger and an integrated composite ballistic screen is constructed with panels and beams made of carbon fiber/vinylester skins over balsa and/or foam cores. Some 20-30 sub-assemblies are used to build just one composite panel. Northrop Grumman won the US$1.4 billion contract to construct the 900 ton composite deckhouse of the DDG 1000 destroyer which is 48.8 m (160 feet) span length, 21.3 m (70 feet) wide and 19.8 m (65 feet) high. The composite parts are made by vacuum assisted resin transfer molding (VARTM) using T-700 carbon fibre and a fire-retardant organobromide vinylester resin over balsa wood cores to meet Navy fire code standards. The deckhouse has the largest panels (36.6m by 18.3m) ever built by the VARTM process and takes up to 12 hours to infuse with resin. Due to cost, only the first two (DDG1000 & 1001) in the series will have composite deckhouses. The lead vessel was launched on 28 October 2013.

More information:

- MR Legault, DDG-1000 Zumwalt: Stealth warship, Composites Technology, February 2010, 16(1), 46-48.

- A McPherson, Composite giants broke the Navy trend, Composites Manufacturing Online, 05 April 2012.

- USS Zumwalt (not USS Enterprise) launched (with video), Materials KTN _connect, 2013.

Ocean Eagle 43 ocean patrol vessel (OPV)

The Ocean Eagle 43 is a new trimaran naval vessel from the legendary multihull yacht designer Nigel Irens, with laminate design by Rivoyre Ingenierie and construction by Chantier Naval H2X, for the shipbuilder CMN. The 43.5 m (142 ft) vessel can cruise at 20 knots for over 4000 km and has a top speed of 30 knots. The materials are mainly infused glass fibre/epoxy sandwich with carbon fibre in the stringer caps and arms that connect the amas (outboard floats) to the main hull. The Corecell foam cores are between 20-40 mm thick with densities in the range 80-200 kg/m3. The main hull infusion used almost 4 tonnes of resin with the complete composite structure weighing <30 tonnes. The infused hulls for the first and second boats differed by <5 kg weight.

Figure 18: Ocean Eagle 43 ocean patrol vessel (OPV). Image source: CompositesWorld

More information:

Sad loss of USS Guardian

The Avenger class MCMVs have a GRP superstructure over an FRP-sheathed oak-and-fir wooden hull with the following specification: 68.3 x 11.9 x 3.5 m and 1040 tonnes full displacement. USS Guardian (fifth in class) ran aground on the UNESCO World Heritage Site Tubbataha coral reef in the Sulu Sea (Phillipines) on 17 January 2013. The Navy was unable to salvage and tow the ship off the reef due to poor sea conditions. Captain Darryn James (spokesman for the US Pacific Fleet) said “The ship is badly damaged” and “after a full review of all possible alternatives, our only viable option is to dismantle the damaged ship and remove it in sections”.

Figure 19: USS Guardian with exposed wooden structure. Image from Gawker Assets

More information:

Fast ferries

| Brødrene Aa (Norway) designed and built the world-first carbon fibre composite passenger vessel in 2002, and had built 50 such vessels at the start of 2016. The Arcadia Alliance joint venture with Front Street Shipyard (Maine, USA) will now build ferries for the North American market.

Figure 20: MS Melkøy is a multipurpose carbon fibre catamaran, taking 97 passengers and 2 cars, equipped with Servogear controllable pitch propellers and designed for a service speed of 25 knots (image from Brødrene website): . |

References

Sterngear (propellers and rudders)

Our former colleague, Tim Searle, considered the use of glass reinforced plastics for marine propellers for both his undergraduate project and his doctoral studies. Four designs of marine propellers up to 660 mm diameter (photograph below) were manufactured in the latter context. Sea trials have been carried out on a 500 mm diameter three-bladed composite propeller installed on a 7-metre work boat with a 40 hp diesel engine. Experiments to measure top speed and the thrust generated with the stern of the boat tied to a bollard have demonstrated that the new propellers give similar performance to traditional bronze propellers. The composite propeller was designed as a retrofit and did not attempt to exploit the potential benefits of hydro-elastic tailoring of the blade material. Tentative finite element models were generated to predict the potential hydrodynamic advantage which may result from such tailoring of the blades by selective fibre placement.

Figure 21: Glass fibre propeller fitted to a University of Plymouth workboat. Image coutesy of Tim Searle

More information:

- T Searle, J Chudley and D Short, Composites offer advantages for propellers, Reinforced Plastics, December 1993, 37(12), 24-26.

- T Searle and D Short, Are composite propellers the way forward for small boats?, Materials World, February 1994, 2(2), 69-70.

- TJ Searle, The manufacture of marine propellers in moulded anisotropic polymer composites, PhD thesis, 1998.

- TJ Searle, Composites final frontier: a composites propeller for commercial marine applications, Design Engineering, April 1999, 51-52.

QinetiQ completed sea trials of a new 2.9 metre diameter composite propeller in Falmouth Bay

during July 2003. Currently the world's largest composite propeller it consists of five composite blades bolted and bonded to a nickel aluminium bronze (NAB) hub and weighs significantly less than an equivalent propeller made from NAB. The propeller was fitted to RV Triton (QinetiQ’s trimaran warship prototype - the world’s largest motor powered triple-hull vessel).

Figure 22: RV Triton and the CFRP propeller. Image sources: left and right © QinetiQ

More information:

- Anon., Composite propeller for warship propulsion – construction and advantages of the composite propeller, AZoM.com, 22 August 2003.

- World's largest composite propeller successfully completes sea trials, Naval Architect, July/August 2003, 16.

- G Hardy, New composites reduce cavitations in giant marine propeller tests,

Materials World, July 2003, 11(7), 8.

Airborne Composites supplied the Royal Netherlands Navy

(RNLN) with a carbon fibre skin/glass fibre core epoxy composite main propeller for an Alkmaar-class minehunter in September 2010.

The ten Alkmaar-class minehunters were developed in the 1970s by a tripartite collaboration with the French and Belgian navies.

The blades were produced to net shape using the resin transfer moulding process

with a 70% weight reduction relative to the nickel aluminium bronze equivalent. Test runs on the 2.5 m diameter propeller, which is designed to deliver about 1400 kW, will start late in 2010 and continue through 2011.

Bronze ship propellers suffer from (cavitation) erosion which spoils the geometry of the hydrodynamic blade surfaces, giving rise to increased turbulence and hence to vibration and noise.

This effect is particularly undesirable for mine counter-measures vessels as an excessive acoustic signature could trigger the mines that they seek.

The use of composite materials for the ships propellers is expected to reduce the need for inspection and maintenance.

The possibility of hydroelastic tailoring of the fibre orientation is under consideration for improved propeller performance.

Nakashima Propeller Comapny, in collaboration with ClassNK (the Japanese classification society) have installed CFRP propoellers in the side thrusters (September 2012) and a 2.12 m diameter CFRP main propeller (May 2014) on Taiko Maru, a 499 GT chemical tanker owned by Sowa Kaiun YK. The CFRP propeller required 9% less power during sea trials when compared to conventional aluminum-bronze propellers.

More information:

- Composite propeller for Dutch minehunter, NetComposites News, 12 November 2010.

- Sara Black, Composite propellor for Royal [Dutch] Navy minehunter, High-Performance Composites, September 2011, 19(5), 70-72.

- W Leenders and M van Santen, Composite main propeller for Dutch minehunter, EuroNaval, Paris, 25-29 October 2010.

- ClassNK and Nakashima Propeller Announce World’s First Installation of a CFRP Propeller on a Merchant Vessel, ClassNK press release, 29 August 2014.

- Carbon fibre propeller cuts fuel costs for Japanese tanker, Reinforced Plastics, September–October 2014, 58(5), 4.

- S Black, Boat propellers with replaceable, interchangeable blades, CompositesWorld, March 2016, 2(3), 68-71.

The US Navy has developed a rudder for DDG-51-class destroyers that twists in such a way that it presents a different angle of attack at different water depths [Griffiths]. Although initially

designed in metal, composite rudders (4.3m across both the span and widest portion of the chord) are now produced for about half the steel rudder cost by Structural Composites using the Recirculation Molding process - a variation on light RTM. The links illustrate the

design, actual rudder as fitted to

USS Bulkeley, the

composite clamshell mould and the

manufacture.

More information:

A team at the University of Southampton studied feather shafts and found they were made of a multi-layered fibrous composite material which allows the feather to bend and twist to cope with the stresses of flight. They foresee applications of their findings in yacht masts and propeller blades.

More information:

Green Marine (Lymington, UK) built a 7.5 m long rudder stock designed by Dubois Naval Architects for a 66 metre sloop using ~1 tonne of carbon fibre prepreg.

More information:

Other propeller applications:

- Anon., Advanced Propulsion System for Fishing Vessels, Design Optimisation and Guidelines for Multimaterial Applications (DOGMA) project, INASMET, 21 December 2000.

- Anon., Long fiber propellers are low cost alternative to metal, Reinforced Plastics, July/August 2015, 59(4), 153.PJ Maljaars, ML Kaminski and JH den Besten, Finite element modelling and model updating of small scale composite propellers, Composite Structures, 15 September 2017, 176, 154–163.

- C-C Lin, Y-J Lee and C-S Hung, Optimization and experiment of composite marine propellers, Composite Structures, June 2009, 89(2), 206–215.

- MR Motley, Z Liu, YL Young, Utilizing fluid–structure interactions to improve energy efficiency of composite marine propellers in spatially varying wake, Composite Structures, October 2009, 90(3), 304-313.

- CD Wozniak, Analysis, fabrication and testing of a composite bladed propeller for a Naval Academy Yard Patrol (YP) craft, Trident Scholar Report, United States Naval Academy report USNA-TSPR-341, Annapolis MD, May 2005.

Power boats

Very Slender Vessels

The first VSV™ was conceived as a high speed power boat to seat up to six and carry them across the Irish sea in relative comfort in all but the worst sea and weather conditions. The MkI 30ft VSV™ was designed by Adrian Thompson for Nick Keig who owned and built the vessel. The vessel was constructed from high tech composite materials and was fitted with petrol V8 engine and Hamilton waterjet drive system. The vessel was launched and proved all the sceptics wrong when it was seen to be an extremely fast and easy to handle boat. Many different variant VSV™ have since been procured by military customers both in the UK and abroad.

Figure 23: Very Slender Vessel (VSV). Image from http://www.vsvboats.com/

The Cable & Wireless Adventure was a bid to circumnavigate the globe by motor-powered vessel in less than 80 days, so as to break the world record. The boat (41 tonnes, 35 x 14 m) is constructed in "composite glass reinforced polymer/foam sandwich". Cable & Wireless Adventurer successfully completed a record breaking circumnavigation. Departing from Gibraltar on 19 April 1998, the vessel returned on 03 July having covered the 24500 nautical miles in 74 days 20 hours, spending some 62 days at sea. The average speed achieved was 16.5 knots and the average fuel consumption about 1 mpg (4.5 litres/nm).

Figure 24: Cable & Wireless Adventure powerboat. Image sources:

left and right.

More information:

Mako Mark V1 Special Operations Craft

Mako, an all carbon-fiber US$15M prototype USN Special Operations Craft (SOC) 50+ knot patrol boat was launched on 11 January 2008. The 25.3 m (83 foot) LOA by 5.2 m (17 foot) beam 57 tonne displacement design was driven by the need for SOC to “operate in rough seas while minimizing the vertical acceleration, or "slamming" felt by Special Operations crew when the boat hits a wave".

Figure 25: Mako Mark V1 Special Operations Craft. Image source

More information:

Earthrace trimaran

Launched 22 February 2006, this radical 24m wavepiercer trimaran by Craig Loomes Design Group (CLDG) was built to try to beat the 75 day record set by Cable & Wireless in 1998 for the Union Internationale Motonautique (UIM) powerboat record for an equatorial circumnavigation via the Panama and Suez canals. Construction is "advanced composites including carbon fibre and aramid reinforcements, toughened epoxy resins and lightweight foam cores". The boat is powered by biodiesel, showcasing the "environmental benefits of this emerging fuel technology". Germanischer Lloyd, in conjunction with CLDG, have analysed the sea induced loadings: the animation below shows the vessel operating at 28 knots in a short steep head sea of 2.8m height and 23m wavelength. The colours indicate the wave peaks and troughs. Between 27 April and 27 June 2008, the boat completed the 24000 mile course in 60 days 23 hours and 49 minutes, reducing the record by almost 14 days (close to a 20% reduction in the time).

Figure 25: Earthrace trimaran. Image source: Craig Loomes Design Group with permission granted by e-mail of Sun 12/03/2006 21:33

More information:

- Auckland - no ordinary show,

http://www.ybw.com/auto/newsdesk/20060208201405ywnews.html, accessed 08:37 on 10 March 2006.

- Craig Loomes Design Group News,

http://www.cld.co.nz/news.htm, accessed 08:25 on 10 March 2006.

- Earthrace Wavepiercer Trimaran,

http://www.cld.co.nz/earthrace.htm, accessed 08:33 on 10 March 2006.

- Earthrace breaks world record thanks to composite industry support, JEC

Composites magazine, September 2008, (43), 44-45.

Palmer Johnson 48-meter SuperSport all-carbon composite superyacht

Palmer Johnson (Sturgeon Bay WI, USA) have delivered their first 48 m (157-ft) SuperSport wave-piercing bow model with twin aft-end sponsons enabling an 11 m (36-ft) beam. The CFRP hull and deck were subcontracted to Brødrene Aa (Hyen, Norway). The lightweight structure is claimed to achieve 50% greater fuel efficiency with speeds up to 32 knots powered by twin MTU 16V 2000 M94 engines. The reduces slamming and pitching in head seas at speed. Though the main hull is slender, the innovative monohull design includes that increases natural stability by a factor of three while offering 30% more interior living space than more traditional models. alternative models in the series include 35 m (115-ft) and 72 m (236-ft) versions.

Figure 27: Palmer Johnson 48-meter SuperSport all-carbon composite superyacht. Image source CompositesWorld

More information:

Christensen 186

High Modulus has commenced the structural design of a 57m (186ft) all-composite motor yacht which was expected to be the largest vessel of this type at the planned launch date of 2011. The production vessel will be vacuum-infused and will break the 500 ton gross-weight threshold.

It relies on the Christensen Shipyards (Vancouver, Washington) proven hull and associated systems. Tooling will start in early 2008, with construction in a new purpose-designed facility on a lakefront in Tennessee. The first boat is allocated to current Christensen yacht owner John Rosatti. Build appears to currently be "on hold".

More information:

- High Modulus to engineer largest all-composite motoryacht, http://www.high-modulus.com/news/Christensen.htm, 9 January 2008.

- The largest all-composite motor yacht, http://www.jeccomposites.com/composites-news/4332/marine-infusion.html, 16 January 2008.

- Largest all-composite yacht, Superyacht News, 17 January 2008.

- High Modulus to engineer the largest all-composite motor yacht, http://www.netcomposites.com/news.asp?4763, 21 January 2008.

- Construction of the world's largest composite motoryacht underway, High-Performance Composites, March 2008, 16(2), 32.

Yachts

There are a number of books appropriate to yacht design:

- AR Claughton, JF Wellicome and AJ Shenoi, Sailing yacht design: theory, Longman, Harlow, 1998. ISBN 0-582-36856-1.

- AR Claughton, JF Wellicome and AJ Shenoi, Sailing yacht design : practice, Longman, Harlow , 1998. ISBN 0-582-36857-x.

- L Larsson and RE Eliasson, Principles of Yacht Design, Adlard Coles Nautical, London, 2007. ISBN 978-0-713-67855-0.

Mirabella V: 740 tonnes - 75.2 m long - carbon/aramid/glass sandwich

construction

The Ron Holland designed Mirabella V is the largest single mast (sloop rigged) yacht in the world. Built by Vosper Thornycroft, she was launched in November 2004 with her 90 m mast stepped in late December of that year. She displaces 740 tonnes and is 75.2 m long. Materials of construction are carbon (deck and stiffeners), aramid (outside hull skin), and E-glass composites over PVC or polyolefin foam cores.

.............................

.............................

.............................

.............................

Figure 28: Mirabella V (subsequently M5). Image source: Mirabella yachts.

Mirabella, refitted in 2013 by Pendennis Shipyard is now sailing as the 77.6 m "M5" with a stern extension, new keel and rudder updates and her original conventional steel rod rigging replaced with lighter carbon textile rigging.

More information:

B&Q Castorama Trimaran - 8.3 tonnes - 23 m long - 30.6 m mast - "constructed

entirely .. of carbon fibre"

Designed by Nigel Irens and Benoit Cabaret

On 7 February 2005, Ellen MacArthur became the

fastest sailor to complete a solo non-stop circumnavigation of the globe (71

days, 14 hours, 18 minutes). The previous record, set in 2004 by Frenchman

Francis Joyon was 72 days 22 hours 54 minutes and 22 seconds. In 1998, the

powered trimaran Cable & Wireless Adventurer (see above) took 74 days 20 hours

with fourteen crew!

Figure 29: B&Q Castorama Trimaran. Image sources:

diy.com (left) and

Solar Navigator (no longer available ~ right)

More information:

Record-breaking one piece SCRIMP motor yacht hulls (After You and Lady Leila (formerly Miss Rose)) were constructed at Horizon Yachts subsidiary Atech Composites (Kaohsiung, southern Taiwan). The Espinosa designed Horizon 130 has an overall length of 39.62 meters, a beam of 7.98 meters and a displacement of 211 tonnes and, at the time of launch, was the longest one piece SCRIMP yacht hull ever attempted in the world.

L’Hydroptère

L’Hydroptère is a concept/trade name of Alain Thébault. After 20 years research and several models, he has built an 18.3 m (60-foot) vessel using "carbon fibre composite and titanium structures" and weighing just 6.5 tonnes:

Figure 30: L’Hydroptère setting a new record south of Lorient (Brittany). Image source: L’Hydroptère

In 2007, she claimed a record speed of 46.5 knots (>86 km/h). The World Sailing Speed Record Council (WSSRC) has ratified two world records for l’Hydroptère, set on Wednesday 04 April 2007:

- the fastest sailing vehicle over one nautical mile with an average speed of 41.69 knots (previously held by Bjorn Dunkerbeck with an average speed of 41.14 knots on a sailboard in 2006).

- the speed record over 500 meters in category D (sail surface area over 27.88 m²) with an average speed of 44.81 knots held since 1997 by the catamaran Techniques Avancées with an average speed of 42.12 knots).

On 04 September 2009 in the Hyères harbour (near Marseille in southern France) in a 28-knot (32-mph) westerly wind, Alain Thébault and his crew achieved 51.36 knots (59.1 mph) over a distance of 500 metres and 48.72 knots (56 mph) over one nautical mile. These figures are subject to ratification by the World Sailing Speed Record Council (WSSRC).

More information:

BMW Oracle

On 14 February 2010, the BMW Oracle trimaran won the 33rd America's Cup in waters off the coast of Spain beating the Alinghi catamaran. The vessel had a 57m (190 foot) composite fixed-wing sail reportedly made using a carbon fiber and aramid-reinforced polymer spar and ribs, wrapped with a polymer film skin.

More information:

SailRocket

Designed by Malcolm Barnsley (UK), Vestas SailRocket is a radical sail foiler. The first objective of the SailRocket team was to return the World Water Speed Sailing Record to the UK requiring speed under sail in excess of 47 knots over the 500m course, with a second objective to raise the world record to the magic and elusive target of 50 knots and rightfully lay claim to the title of ‘the worlds first 50 knot sailing machine’. On 03 December 2008 at the Walvis Bay speed-strip in Namibia, Paul Larsen piloted SailRocket at an average speed of 47.36 knots (54.5 mph) over a 500m course with peak speeds of 52.22 knots.

Figure 31: SailRocket. Image sources:

Sailing Scuttlebutt (left) and Bang The Corner (right)

On 16 November 2012, Vestas SailRocket broke the outright world speed sailing record at Walvis Bay in Namibia when it reached speeds of 59.23 knots (around 70 mph) over the 500m (1625 ft) course. The peak speed was 62.53 knots in winds of just 25 knots. On 28 November 2012, the SailRocket achieved an average 65.37 knots (121.21 km/h) certified by the World Sailing Speed Record Council (WSSRC) with a top speed above 67 knots. The main structure is an autoclave-cured sandwich of carbon/epoxy prepreg skins over an aramid honeycomb core. The sail is built around a carbon tube acting as a spar with polyester film wingskins.

More information:

- Composites at work for the world sailing speed record, JEC Composites magazine, December 2014, (93), 46-47.

- Cutting edge Vestas Sailrocket tops 52 knots, survives spill in record run, High Performance Composites, January 2009, 17(1), 11.

-

Gurit helps Vestas sailrocket break record, Composites World, 8 December 2008.

- New version of SailRocket aims to break sailing speed world

record, High-Performance Composites, May 2011, 19(3), 22-23.

- SailRocket (whbs.demon.co.uk)

- SailRocket model tests (movie)

- The World's Most Radical Boat Designs - SailRocket

- Vestas Sailrocket sets new speed record: the high-speed catamaran with wing sail, custom-built for the record run, is made with composite materials, CompositesWorld, 26 November 2012.

- L Reade, Sailing off with a world record, Composites in Manufacturing, April/May 2016, 14-17.

Team Philips/Goss Challenge

The revolutionary catamaran "Team Philips" was the dream of one man, Pete Goss. At 37 m by 21 m (120ft long, 70ft wide .. larger area than the centre court at Wimbledon) and 41 m high, the catamaran construction was closer to aerospace techniques than boat building - using preimpregated fabrics and vacuum-bagging. With wave piercing bow technology, she was a sailing spaceship in carbon fibre, and was specifically designed for The Race - a no-holds barred, no limits, round the world challenge. On its first seatrials, a large portion of the portside pontoon snapped off. The cause of the failure was identified, repairs made, and the boat relaunched for another seatrial. Just one day into that trial, near the Scilly Isles, trouble developed in one of the huge rotating wing masts. In December 2000, on the passage to the start of The Race in Barcelona, Team Philips had to be abandoned in freak weather: 70 knot winds, 10m waves and worsening weather conditions, left Pete and his crew no choice but to abandon Team Philips or risk their lives.

Figure 32: Team Philips/Goss Challenge. Image sources: NMMC (left) and BBC News (centre and right)

More information:

Motor Boats and Yachts

More information:

Rigging: (wing-)masts and sails

The German engineer Anton Flettner proposed the use of vertical metal wings to replace sails in 1920 [1]. The British aeronautical engineer John Walker designed the Walker Wingsail and launched the Planesail catamaran with Wingsails in 1966. In the late 1990s, Harbor Wings (Mark Ott, David Hubbard and Sam Bradfield) developed the radical multi-hull open-ocean racer, Volantis, and subsequently an unstayed all-composite WingSail which is free to rotate in any direction

and through the full 360° around the mast. The WingSail has been combined with the HWT X-3 catamaran to produce a fully-autonomous unmanned sea vessel (AUSV) [1]. Mazza [2] has recently reviewed the use of modern composites and advanced software in the development of the "hard" wing sails that have changed the nature of high-performance racing.

Maltese Falcon (1200 tonnes steel/aluminium hull - 87.5 m long overall) is a US$100M superyacht with an overall length of 87.5 m and three free standing masts (each one is 57 m high and weighs 13 tons) which permits rotation of the mast to optimally catch the wind [3-7]. The carbon-fibre composite masts have embedded optical fibre sensors which report strain and stress data to the bridge. The vessel has a clipper rig based on the DynaRig concept developed in the 1960s by German hydraulics engineer Wilhelm Prolls. There are six curved carbon-fibre yards to each mast. In performance trials, she achieved 10.5 knots hard on the 15.8 knots true wind at 38 degrees relative wind angle with the topgallants and the royals furled. On a close reach at 60 degrees relative angle, the speed (still at 16 knots true wind) climbed to 14 knots.

Figure 33: Maltese Falcon. Image sources: Luxist (left) and YBW (centre and right)

|

Magma Structures (Portsmouth) has delivered three 100m+ free-standing 50 tonne rotating carbon composite masts for a sailing superyacht under construction in a Kiel (Germany) shipyard [8-10]. The masts were designed by Dykstra Naval Architects (NL) to withstand bending loads of more than 40MN (more than twice the load on a Boeing Dreamliner wing). They support a sail area greater than a standard sized football pitch, with full automation in terms of sail deployment, setting and reefing. The masts have embedded fibre optic monitoring to permit optimised sailing performance, to verify the design concepts and to acquire load case data to minimise maintenance.

Figure 34: Magma Structures masts.

Image sources: Materials Today (left)

Magma Structures (right). |

|

Scalvini [11 has presented a case study of the limits of non-destructive examination techniques in assessing lightning damage to a 39 m carbon/epoxy composite mast which was struck by lightning. A lightning strike might deliver 200k amps at tens of kilovolts in a fraction of a second. Absence of appropriate shielding, or an adequate conductive path to ground, is likely to result in various damage modes including matrix cracking, intraply damage and delamination. Laser shearography with dynamic excitation indicated that one side of the mast had different characteristics to the other. Static shearography,

thermography and ultrasonics did not reveal any obvious damage.

|

The fibres in a FiberPath laminate sail are aligned with the primary loads in the sail, and a FiberPath sail can be built with multiple fibre patterns to address secondary loads. In addition, a FiberPath sail is lighter in weight than a tri-radial sail and is aimed at a grand prix applications. In 2007, North Sails [12] acquired Swiss intellectual property to produce an anisotropic soft 3DL sail membrane system with specific fibre placement in a Mylar film sandwich designed to take the design loads on the sail. Their most recent development [12, 13] is the 3Di system which uses very thin (1-1.5 μm) spread tow unidirectional prepreg tapes to produce quasi-isotropic laminates and eliminate the Mylar film.

Figure 35: FiberPath laminate sail. Image source: Skelley Sails. |

| The Wind Challenger Project, a Japanese industry-university joint research project launched in October 2009, is developing rigid, retractable sails for cargo ships that harness wind-power and reduce both fuel consumption and CO2 emissions. The full-scale sails are expected to measure 50x20 m (i.e. 1,000 m2) in area. Small-scale sails (20x8 m) made of glass fiber reinforced plastic skins over a foam core were delivered in January 2014 for on-land testing in Nagasaki. The test vessel will have five 15 m high retractable sails.

Figure 36: Four Wind Challenger sails on a VLCC. Image source: MOL Service |

Reference

- S Black, Sailing the sea with composite wings - autonomous sailing vessel patrols with patented WingSail technology, Composites Technology, April 2012, 18(2), 46-48.

- R Mazza, Wings of change .. and .. Winged history, Professional Boatbuilder, October-November 2011, (133), 70-82.

- S Black, Megayacht composite masts get "smart", High-Performance Composites, January 2007, 15(1), 44-46.

- Maltese Falcon megayacht launched with "smart" masts and yards, Composites World, September 2006, 14(5), 12.

- UK Company Engineer Rig for $100 Million Superyacht, NetComposites News, 6 July 2006.

- Maltese Falcon has landed, Yachting World, 13 June 2006.

- The Maltese Falcon log

- Magma Structures delivers world's tallest masts, http://www.materialstoday.com/carbon-fiber/news/magma-structures-deliver-worlds-tallest-masts, Reinforced Plastics/Materials Today, 16 October 2015, accessed 24 October 2015.

- Sailing Yacht A starts sea trials in Germany, accessed 26 October 2015.

- Introducing the world's tallest carbon composite, free-standing superyacht masts, accessed 26 October 2015.

- R Scalvini, Carbon and lightning, Professional BoatBuilder, December/January 2011, (128), 50-61,

- D Dawson and K Reque, Custom-engineered composite performance yacht sails, High-Performance Composites, March 2012, 20(2), 62-64.

- WE Pearson, Textiles to composites: 3D moulding and automated fibre placement for flexible membranes, Chapter 14 in J Graham-Jones and J Summerscales (editors), Marine Applications of Advanced Fibre-Reinforced Composites, Woodhead Publishing, Cambridge, 2015, 305–334.

More information:

- John Burnham and Tony Bessinger, Changes in Racing Sails and Sailmaking, Sailing World, 03 May 2004

- Bob Fraser, All About D4, Doyle’s Tough and Affordable Engineered-Laminate Sails, Silver Threads newsletter, 2003

- Tim Stodola, Laminated Sailcloth — A Cruising Option, Southwinds Media, 30 September 2002

- Sven Donaldson, Voyaging laminates, Ocean Navigator #56, September/October 1993

- Racing sails - why Fiber Path? (Ullman Skelley Sails).

- R Pemberton and J Graham-Jones, Application of composite materials to yacht rigging, Chapter 12 in J Graham-Jones and J Summerscales (editors), Marine Applications of Advanced Fibre-Reinforced Composites, Woodhead Publishing, Cambridge, 2015, 279-194.

- B Fallow, Computational fluid dynamics (CFD) sail shape optimisation, Chapter 13 in J Graham-Jones and J Summerscales (editors), Marine Applications of Advanced Fibre-Reinforced Composites, Woodhead Publishing, Cambridge, 2015, 295-303.

Canoes, kayaks, surfing etc.

The Pink Lady Atlantic row set off from St John's, Newfoundland on June 30 and was within days of breaking a world record for the fastest North Atlantic row from Canada before it was stopped by a freak wave. The structure of the boat is a carbon fibre/foam core sandwich built in four separate components (10 meter hull, forward cabin roof, the aft cabin roof and the rowing bay) joined together in the final stages of construction by a four-man Goss Composites team.

Figure 37: Go Pink Lady. Image source: Go Pink Lady.

The Knoydart 14' Prospector is available in a wide variety of lay-ups. The standard fibreglass lay-up (24kg) is ideal for entry level paddlers, while the Ultralight version (18kg) provides one of the lightest solo canoes available for wilderness tripping. "It is a serious all-around solo canoe that is responsive and seaworthy in grade II and III white water and yet it’s efficient enough to paddle across large bodies of open water".

Figure 38: Knoydart 14' Prospector. Image source:

Knoydart

Solway Dory produce sailing canoes including the

Avocet open-double and fibreglass versions of the

Curlew open single.

More information:

Perkins has briefly reviewed the use of materuials within surfing.

More information:

Fish farm

AgriMarine Holdings (Vancouver BC) have produced a 24 m diameter fish farming system. The 3000 m3 GFRP tank is claimed to have significantly higher salmon output per volume than conventional fish farming environments. The GFRP tank uses 48 sections fabricated by vacuum infusion with six tools. An epoxy vinyl ester resin was specifically selected for corrosion resistance.

Figure 39: The AgriMarine SystemTM tank deployed in a farm in Lois Lake, British Columbia. Image source: Composites Manufacturing

More information:

- Building a better fish farm out of GFRP, Composites Manufacturing, 30 April 2015.

Natural fibres and bio-based resins

Flaxcat is a light-weight catamaran built and sailed by Niels Haarbosch and Thomas Mol (Students at Delft University of Technology - Netherlands) [1,2]. The vessel is made of

natural fibres (the Dutch website says "vlas" i.e. flax, but the English translation has hemp!) in epoxy resin.

At APC Composites (Luleå - Sweden), Gustafsson has produced the hull of a

small boat using flax fibres in bio-based furan resin by vacuum infusion [3].

The Araldite (a 6.5 metre racing yacht sponsored by Huntsman Advanced Materials)

[4-8] was launched on 9 September 2010 and built to compete in the 6.50 ClasseMini series:

- the Mini Empuries (18 September 2010): a two-handed prototype race of 300 miles around the Balearic Islands with the finishing line at L’Escala in Spain. Araldite (791) withdrew "for problems in the direction of the vessel").

- the Mini Barcelona solo race (16 October 2010): a 300 mile race starting and finishing in Barcelona. Araldite (791) was placed tenth of 17 boats.

- the Mini Transat 6.50 race from La Rochelle (France) via Madeira to Salvador de Bahia (Brazil). Araldite finished in 15th place on 02 November 2011 after 28 days and 20 hours at sea.

Figure 40: The Araldite eco-friendly mini transat 6.50 sailing boat prototype made with hybrid carbon/flax fibre reinforcement.

Image from Lineo.

Araldite uses flax fibres treated with an epoxy resin coating at Lineo in Belgium to prevent absorption of water into the flax, to promote adhesion to the epoxy and to extend the temperature resistance to 250°C and hence allow prepregging. Structures including the hull, deck, helm and toe-rails were built by IDB Marine de Tregunc in Brittany using 50% flax fibres and 50% carbon fibres.

Flaxland (UK)

[9, 10] have built a canoe using one layer of

Composites Evolution

Biotex Flax Hopsack weave and

Sustainable Composites

EcoComp UV-L ultraviolet-cure linseed-based bioresin to

cover a marine plywood and pine frame. Flaxland are reported to have made

seven prototypes using both the Biotex Flax Hopsack (net weight under 12 kg) and Biotex 3H Satin weaves (8 kg) for racing. The canoe has shown good results during long term (over one year) "durability and water resistance tests".

Campion Marine has announced that it will manufacture all new

boats with Ashland Performance Materials Envirez® bio-derived soybean oil and corn derived ethanol resin [11]. Ashland claim that the change will reduce carbon dioxide (CO2) missions to the atmosphere by more than 45k tonnes.

The Breton NavEcoMat collaboration have produced the 4 m 30 kg Naskapi demonstrator canoe entirely from flax fibre and PLA (polylacticacid) biocomposites

using the vacuum-bagged film stacking technique [12].

Bosser et al [13] have described the design, development and manufacture of a resin-infused all-flax composite 7-metre prototype trimaran "Gwalaz" launched in May 2013 and based on the Tricat (glass/polyester/foam) design. Gwalaz is constructed using 109 kg flax fibres in 280 kg bio-based polyester resin with 33 kg of balsa, cork and plywood as core materials.

The Gold of Bengal association has launched a 100% jute fibre reinforced polyester resin biocomposite sailboat [14]. The Pàt technical jute fibre (ρ = 1.44, EUD = 19.8 GPa, σ' = 165 MPa) was specifically designed for composite applications. The vessel has sailed around the Bay of Bengal for six months.

Lake Constance, a German canoe designer, has used vacuum-infused Composites Evolution Biotex flax for its "Felicity" agile solo freestyle/touring canoe [15-17].

Grand Largue Composites (Mondeville, France) used Sicomin (Châteauneuf les Martigues, France) fibres, fabrics, epoxy resin and adhesives to construct the yacht "Crosscall" which won the Class40 World Championships in June 2022. The racing yacht features a significant quantity of flax fiber reinforcements with hybrid biaxial fabric for the cockpit and flax in the tunnel, engine cover, ballast tanks and cap [18].

More information:

- If you dont smoke it, sail it, Delft University of Technology, 07 April 2002.

- Moeder natuur helpt de industrie een handje, Delft University of Technology, 4 March 2004.

- New Classes of Engineering Composites Materials from Renewable Resources, Final Report on European Commission Framework Programme 6 Project NMP2-CT-2005-515769 BIOCOMP, November 2008.

- Araldite sponsors pioneering eco-friendly Mini Transat 6.50 sailing boat prototype, DPA: The Engineer's Guide to New Products and Design Ideas, 09 September 2010.

- Eco-friendly Mini Transat 6.50 sailing boat prototype, NetComposites, 19 September 2010.

- Racing yacht construction part-replaces carbon fibre with flax, British Plastics and Rubber, October 2010, 34.

- A flax-composite boat for transatlantic races, JEC Composites magazine, August-September 2011, (67), 33-34.

- Flax fiber racing boat completes Transat race, Composites World, 14 November 2011.

- Flaxland create canoe from Composites Evolution's Biotex Flax, accessed on 12 October 2011.

- Flaxland produce flax canoe/kayaks, accessed 12 October 2011.

- Campion Marine selects Ashland bio-based resin for all new boats, Reinforced Plastics, March-April 2010, 54(2), 8. Online, 14 January 2010.

- First small watercraft that is compostable at end of life, JEC Composites magazine, March 2012, (71), 24 (webpage requires registration).

- L Bosser, E Poisson, E Grossman and P Davies, The first all-flax composite trimaran, JEC Composites magazine, October 2013, (84), 33-35 (webpage requires registration).

- J de Mony-Pajol, C de Chatelperron and G Cail, The first 100% jute reinforced biocomposite sailboat, a prototype of importance in bangladesh, JEC Composites magazine, 2014, 87, 76-77 (webpage requires registration).

- Flax reinforced composite used in lightweight sports canoe, Reinforced Plastics website, 10 September 2014.

- Lightweight sports canoe relies on flax fiber reinforcement, Composites World, 15 September 2015.

- Biotex floats the boat, Composites in Manufacturing magazine, September 2014, 6.

- G Nehls, Grand Largue Composites, Sicomin enable flax fiber-built Class40 racing yacht, 09 November 2022.

Composites and fire (Safety of Life at Sea (SOLAS) Regulations)

The Maritime and Coastguard Agency (MCA) held a meeting on 10 March 2011 in

Southampton to discuss a UK submission to the next IMO (International Maritime

Organisation) Sub-Committee on Fire Protection on the difficult subject of

using composite materials structurally in ships. In February 2015, the IMO SDC (Ship Design and Construction) meeting provisionally approved the Guidelines to accept a FRP composite ship design in the context of fire safety issues (Tommy Hertzberg e-mail to E-LaSS participantsof 23 February 2015).

Also see: Indonesian stealth boats

Video: Princess 95 yacht "Queen Anna" on fire in Fethiye.

Fiberglass exhaust tube offer lasting durability

Thermoplastic matrix structural marine composites

End-of-Life (EOL) vessels and wind turbine blades.

- H Bel Haj Frej, R Léger, D Perrin, P Ienny, P Gérard and J-F Devaux, Recovery and reuse of carbon fibre and acrylic resin from thermoplastic composites used in marine application, Resources, Conservation and Recycling, October 2021, 173, 105705.

- S Job, G Leek, PT Mativenga, G Oliveux, S Pickering and NA Shuaib, Composites recycling: where are we now?, Composites UK, 2016.